Two Arms Shuttle Rotomolding Machine

Two Arms Shuttle Rotomolding Machine

Two Arms Shuttle Rotomolding Machine The shuttle machine series features a central oven, two operational stations, and two carts equipped with either straight or offset arms. the machine includes two cooling stations, offering an exceptional balance of productivity and cost efficiency. Shuttle style rotational molding machine is placed along a straight line with oven and two trolleys with arms in its center. cooling chamber and loading station in both sides.

Two Arms Shuttle Rotomolding Machine

Two Arms Shuttle Rotomolding Machine Rotomolding is often used for parts that require high quality finishes, uniform wall thicknesses, and high stability. features such as inserts and spin weld attachments can be incorporated directly into the rotomold and foaming can be used to create thermal insulation and stiffness. Benfan has recently loaded and shipped two 3 meter shuttle rotomolding machines! these two rotomolding machines are custom made for the client, each equipped with two straight arms, doubling efficiency, and boasting powerful performance, helping customers with their rotomolding processing!. Rotational molding, also known as rotomolding, is a manufacturing technique used to produce hollow plastic products. a shuttle rotomolding machine consists of a large oven, a mold, and a shuttle system. the oven is heated to melt the plastic material, typically a powdered resin, inside the mold. Most shuttle machines have two arms that moves the molds back and forth between the heating oven and cooling station. the arms are independent of each other and they turn the molds bi axially.

Two Arms Shuttle Rotomolding Machine

Two Arms Shuttle Rotomolding Machine Rotational molding, also known as rotomolding, is a manufacturing technique used to produce hollow plastic products. a shuttle rotomolding machine consists of a large oven, a mold, and a shuttle system. the oven is heated to melt the plastic material, typically a powdered resin, inside the mold. Most shuttle machines have two arms that moves the molds back and forth between the heating oven and cooling station. the arms are independent of each other and they turn the molds bi axially. We focus on rotomolding equipment, slush molding equipment, rotomolding molds and rotomolding products,customizes the design according to the needs of each customer,so as to achieve the coexistence of service and quality. This machine maximum reliability and simplicity in use. an ideal machine for high volume production of articles, even of different sizes with similar working cycles. Shuttle style rotational molding machine is placed along a straight line with oven and two mainframes in its center. cooling chamber and loading station in both sides. when one arm on one side rotating the mold into the oven to get heated, the molds on other arm can be demoulded or adding material. Our expertise in rotational molding (rotomolding) allows us to deliver tanks that are durable, safe, and cost effective—making us the trusted choice for potable water, agriculture, industry, and chemical storage.

Two Arms Shuttle Rotomolding Machine

Two Arms Shuttle Rotomolding Machine We focus on rotomolding equipment, slush molding equipment, rotomolding molds and rotomolding products,customizes the design according to the needs of each customer,so as to achieve the coexistence of service and quality. This machine maximum reliability and simplicity in use. an ideal machine for high volume production of articles, even of different sizes with similar working cycles. Shuttle style rotational molding machine is placed along a straight line with oven and two mainframes in its center. cooling chamber and loading station in both sides. when one arm on one side rotating the mold into the oven to get heated, the molds on other arm can be demoulded or adding material. Our expertise in rotational molding (rotomolding) allows us to deliver tanks that are durable, safe, and cost effective—making us the trusted choice for potable water, agriculture, industry, and chemical storage.

Two Arms Shuttle Rotomolding Machine

Two Arms Shuttle Rotomolding Machine Shuttle style rotational molding machine is placed along a straight line with oven and two mainframes in its center. cooling chamber and loading station in both sides. when one arm on one side rotating the mold into the oven to get heated, the molds on other arm can be demoulded or adding material. Our expertise in rotational molding (rotomolding) allows us to deliver tanks that are durable, safe, and cost effective—making us the trusted choice for potable water, agriculture, industry, and chemical storage.

Two arm shuttle rolling machine

Two arm shuttle rolling machine

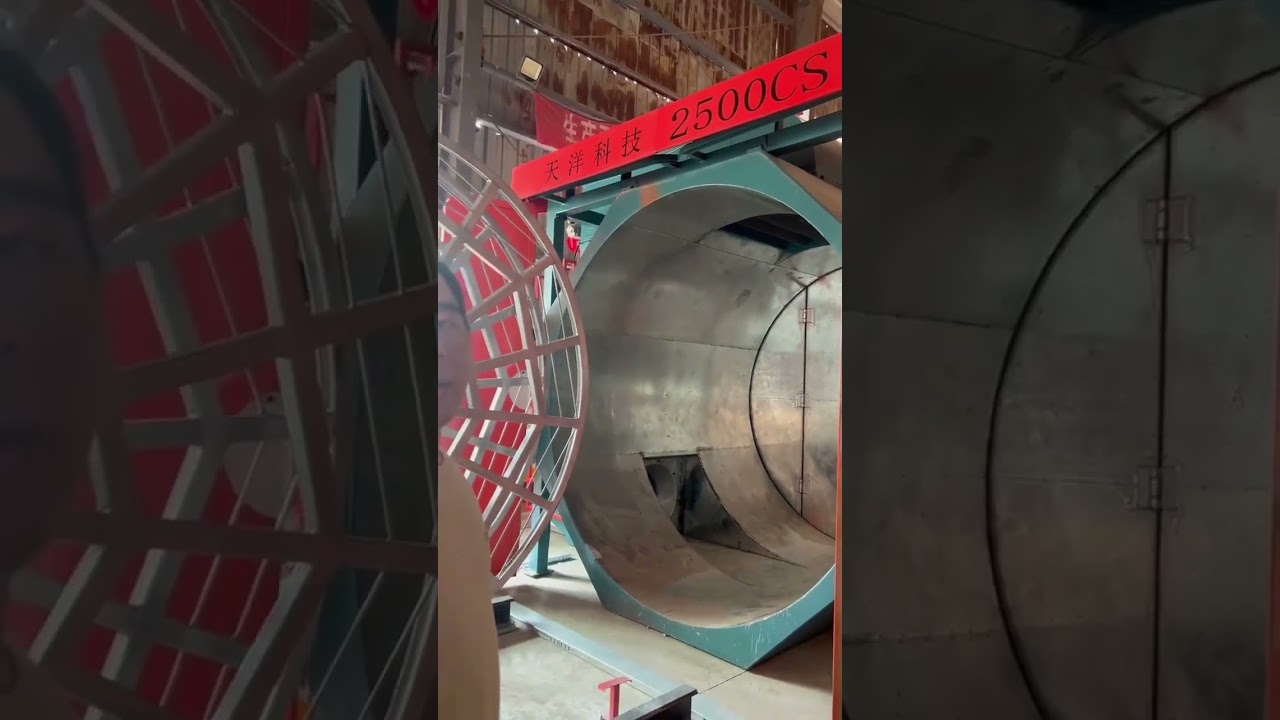

Related image with two arms shuttle rotomolding machine

Related image with two arms shuttle rotomolding machine

About "Two Arms Shuttle Rotomolding Machine"

Comments are closed.